Tempus fugit Usually this Latin expression is veiled with regret, as we humans perceive the passing of events to be too fast, to the point that we are not able to keep track of them. In our case,

Tempus Fugit

Tempus fugit Usually this Latin expression is veiled with regret, as we humans perceive the passing of events to be too fast, to the point that we are not able to keep track of them. In our case,

Cruel nature or ungrateful children? Extract from the magazine AIMAN – MANUTENZIONE & ASSET MANAGEMENT, MARCH 2024 Exploring the role of man in nature’s domestication and environmental challenges, we analyze how climate change, influenced by various dynamic factors, and

The significant benefits – sometimes unexpected – of conditions monitoring Extract from the magazine AIMAN – MANUTENZIONE & ASSET MANAGEMENT, MARCH 2024 In this issue of our magazine, which is growing in following due to its amount of valuable

You’re not born to be an expert in refrigeration, you become it by acquiring specific skills. The tight collaboration between EptaService, part of EptaGroup, and Mecoil Diagnosi Meccaniche strengthens predictive maintenance in the refrigeration sector. On October 5th, 2023, almost

Follow our webinar to learn more about our activities and what you can find out from oil analysis!

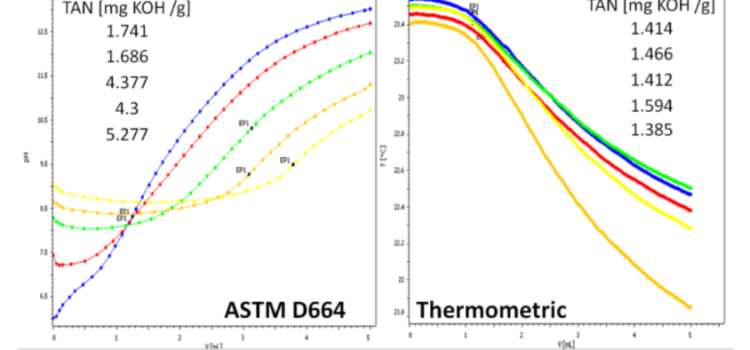

Starting from 2020, TAN analysis will be performed according to the ASTM D8045, a more reliable and repeatable method. The continuous improvement strategy that Mecoil has undertaken since the very beginning, dedicating to oil analysis and predictive diagnosis, requires the

Recent developments of the international research project that promotes Artificial Intelligence for the purpose of Diagnostic Automation have just been published on MATEC. The article, titled The lubricants’ parameters monitoring and data collecting, summarizes the goals obtained in the field

Oil, in its numerous and sometimes complex formulations, is a lubricating fluid that performs endless tasks within the industrial assets. Its “mission” is sometimes heterogeneous, but still aimed to protect the surfaces from the aggression of chemical and physical agents;

On the 11th and 12th of October in Malpensa was held SIMa, the first Italian Maintenance Summit. The meeting, based on the sharing of maintenance issues on several levels, was created thanks to the authority of A.I.MAN., the Italian Association

In 2012, Noria Corporation launched a survey aimed at readers of Machinery Lubrication magazine about the significance of particulate matter in the lubricant in operation (“Particles: Friend or Foe?”). The survey asked if, in modern industrial maintenance procedures, the particulates