There is a need to develop a sampling procedure under standard and repeatable conditions for lubricating oils, hydraulic fluids or combustible products with a high flash point, desired by maintenance operators as well as quality control operators.

In the case of pipelines or tank transports, there are already suitable tapping points or shut-off valves (positioned according to the norm) for drop sampling through gravity.

The situation is different when we find ourselves operating machinery with a separate or non-pressurized carter, or hydraulic circuits tanks.

With these equipment, collecting a meaningful sample representative of the “health conditions” of the oil charge and the machinery itself becomes a critical moment of the process.

“Sampling” procedures are subject to numerous international standards, developed over the years (since the dawn of quality control in chemical processes) and refined as a result of the increasingly pressing requests from Maintenance and Safety Managers.

The search for the “root causes” of failure within the lubricating oil charge has become a widely shared method by several associations, both in the civil field (see ASTM and DIN/ISO regulations) and in various military sectors (JOAP-USA).

There is a clear parallel between what has been developed in the medical field, when it comes to clinical diagnostics (blood tests for preventive medicine), and what has been achieved to circumscribe the incipient damage in critical mechanical systems.

The latest generation aircrafts are equipped with on-board online sensors, but require periodic check-ups of the quality and quantity of any contaminants present within the lubrication circuits.

Large hydraulic presses or hydraulic machines in general, regardless of size, need periodic analyses in order to monitor the quality of the oil in operation.

We only need to take about 100 ml of product, collect it in a suitable container, safe from accidental contamination, and quickly send it to the affiliated laboratory.

In fact, if due to involuntary causes we were to contaminate the container, even a small quantity of environmental dust added to the oil sample would lead to incredibly skewed analytical data.

The normative reference standard is “ppm” (part for million), meaning grams of substances (metals, powders, water) per cubic meter of oil examined. In that case, even a 0.2 g grain of sand (in 100 cc), translated into ppm, could lead us to think that we are in the presence of a circuit contamination of several hundred grams of it.

Or if a fly were to fall into the open vial (whose volume is about 1/10.000 of a cubic meter) and “stupid” machinery were to examine it, you could assume that the oil examined has a contamination level of about 10.000 flies per ton of product!

Our long experience in the field of Machine “Preventive Medicine” (with over 20 years of work in the field) helped us understand that the sampling stage is the weak link of the entire diagnostic process (drawing, sending, reporting).

We have shared this problem with other qualified laboratories around the world and have encountered the same concerns when it comes to the difficulty of certain types of sampling.

Current practices have been developed in various parts of the world to improve this transition, using empirical and sometimes very complex methods.

These include: “vampire” pumps that can be reused several times, but require effort in their practical use; disposable syringes, which have a low capacity and some difficulty in picking up very viscous products; other extemporaneous creations of little real use.

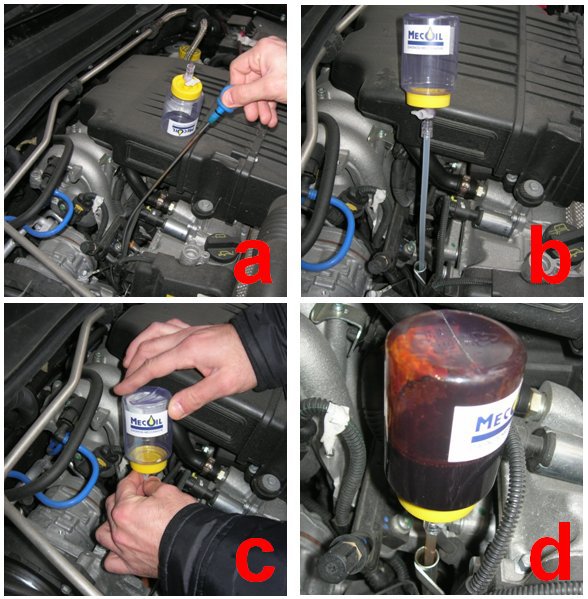

The essential and unique characteristic of the patented system “U.C.V.D.” (Ultra Clean Vacuum Device) is having a container of sufficient volume with a suitable vacuum (borrowing the procedure from blood draws in medicine).

A tap placed on the top of the cap allows us to draw the appropriate amount of fluid to be analyzed, without interference or accidental contamination. This “clean” container, even if not sterile, is also perfectly suitable for the collection of water or other fluids, for analytical purposes where the evaluation of the bacterial charge is not involved. Therefore, it can be used for a wide array of requirements.

One of the advantages of this technology is its ease of use in any situation (therefore granting greater safety for operators, fast service and hands free execution, even in uncomfortable locations) while avoiding unintentional contamination.

It helps decrease the amount of use-as-needed consumables (throw-aways) and increases the certainty of the test/sample and its repeatability (with little influence from human intervention).

Any traces of dust or minimal condensation of atmospheric humidity are removed during the vacuum application, ensuring a micro-environment under controlled conditions, practically anhydrous.

More details can be found in this article.